Khokahano ea Bofokoli ba Kopano ea PCB U Sebelisa Tlhahlobo e Ikemetseng ea Optical (AOI)

Khokahano ea Bofokoli ba Kopano ea PCB U Sebelisa Tlhahlobo e Ikemetseng ea Optical (AOI)

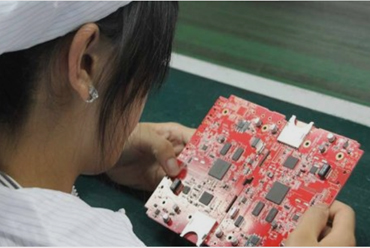

Automated Optical Inspection (AOI), e leng tlhahlobo e itirisang ea pono ea Printed Circuit Board (PCB), e fana ka karolo e bonahalang ea 100% le tlhahlobo e kopaneng ea solder.Mokhoa ona oa teko o 'nile oa sebelisoa ho etsa PCB ka lilemo tse ka bang mashome a mabeli.E bapala karolo ea bohlokoa ho netefatsa hore ha ho na liphoso tse sa reroang kopanong.Mokhoa ona, o sebelisang mabone, lik'hamera, le likhomphutha tsa pono, o kenyelelitsoe ts'ebetsong ea ho kopanya ho netefatsa boleng bo phahameng ka ho fetesisa nakong eohle ea bophelo ba sehlahisoa.Mokhoa ona o nolofalletsa tlhahlobo e potlakileng le e nepahetseng mme e ka sebelisoa maemong a fapaneng a ts'ebetso ea tlhahiso.Kahoo, ke lintho life tseo lisebelisoa tsa Automated Optical Inspection (AOI) li ka li hlahlobangKopano ea PCB?

Ho Fumana Bofokoli U Sebelisa AOI

Ha liphoso li lemohuoa kapele, ho tla ba bonolo ho etsa tlhahiso ea ho qetela e tsamaellane le litlhoko tsa moralo ntle le liphoso.Theknoloji ena e tsebahalang, e amohelehang e ka sebelisoa ho hlahloba tse latelang kopanong ea PCB:

- Maqhutsu, mengoapo le matheba

- Li-circuits tse bulehileng, lifupi le ho fokotseha ha solder

- Likarolo tse fosahetseng, tse sieo le tse khopameng

- Sebaka sa peista se sa lekaneng, ho tlotsa, le borokho

- Li-chips tse sieo kapa tse theolelang, li-chips tse khopameng le bofokoli ba chip-orientation

- Marokho a solder, le lithapo tse phahamisitsoeng

- Litlolo tsa bophara ba mela

- Tlolo ea sebaka

- Koporo e feteletseng, le pad e sieo

- Trace shorts, cuts, jumps

- Litšitiso tsa libaka

- Liphetoho tsa likarolo, polarity ea likarolo,

- Ho ba teng kapa ho ba sieo ha motsoako, karolo ea skew ho tloha holim'a holim'a liphahlo

- Li-solder tse feteletseng le li-solder tse sa lekaneng

- Likarolo tse fetotsoeng

- Beha li-lead ho pota-pota, marokho a solder, le ngoliso ea solder paste

Ha liphoso tsena li lemohuoa ka nako ea pele, bahlahisi ba ka hlahisa boto ho ea ka litekanyetso tse hlokahalang.Ho kenya letsoho lits'ebetsong tsa tlhahlobo, ho na le lisebelisoa tse 'maloa tse fumanehang tse nang le mabone a tsoetseng pele, optics le bokhoni ba ho sebetsana le litšoantšo bakeng sa tšireletso e ikhethang.Mechini ena e fana ka ts'ebetso e bonolo, e bohlale le e matla, e lebisang ho fokotsa litšenyehelo tsa hau tsa rework le ho ntlafatsa ts'ebetso ea tlhahlobo.AOI e le mokhoa oa bohlokoa oa tlhahlobo o khethollang boleng ba kakaretso ba boto, ho bohlokoa ho fumana litšebeletso ho tsoa ho lik'hamphani tse etellang pele.Kamehla ke khetho e nepahetseng ho sebelisana le baetsi ba PCB ba fanang ka tlhahlobo ea AOI ka letsoho.Sena se thusa moetsi ho lekola boto mohatong o mong le o mong oa kopano ntle le tieho.

Nako ea poso: Jun-15-2020