Litaba tsa k'hamphani

-

Mokhoa oa SPI ke Eng?

Ts'ebetso ea SMD ke mokhoa o ke keng oa qojoa oa tlhahlobo, SPI (Solder Paste Inspection) ke ts'ebetso ea ts'ebetso ea SMD ke ts'ebetso ea tlhahlobo, e sebelisetsoang ho bona boleng ba khatiso ea solder paste e ntle kapa e mpe.Hobaneng o hloka lisebelisoa tsa spi ka mor'a khatiso ea solder paste?Hobane data e tsoang indastering e ka bang 60% ...Bala haholoanyane -

Tsebiso ea Matsatsi a Phomolo

Tsebiso ea Matsatsi a Phomolo Baratuoa ba ratehang, Taba ea pele, re rata ho le leboha ka ts'ehetso ea lona e tiileng le e tsoelang pele ho NeoDen.Pls re ele hloko ka lebaka la Mokete oa Machaena oa Mahareng a Hoetla le Matsatsi a Phomolo a Letsatsi la Naha, NeoDen e tla koaloa ho tloha ka la 29 Loetse 2023 ho isa la 6 Oct. 2023 le ho khutlela mosebetsing ka la 7 Oct.2023...Bala haholoanyane -

Hobaneng ha re Lokela ho Tseba ka Packaging e Tsoetseng Pele?

Morero oa ho paka semiconductor chip ke ho sireletsa chip ka boeona le ho hokahanya mats'oao lipakeng tsa lichipisi.Ka nako e telele nakong e fetileng, ntlafatso ea ts'ebetso ea chip e ne e itšetlehile haholo ka ntlafatso ea moralo le ts'ebetso ea tlhahiso.Leha ho le joalo, joalo ka sebopeho sa transistor sa ...Bala haholoanyane -

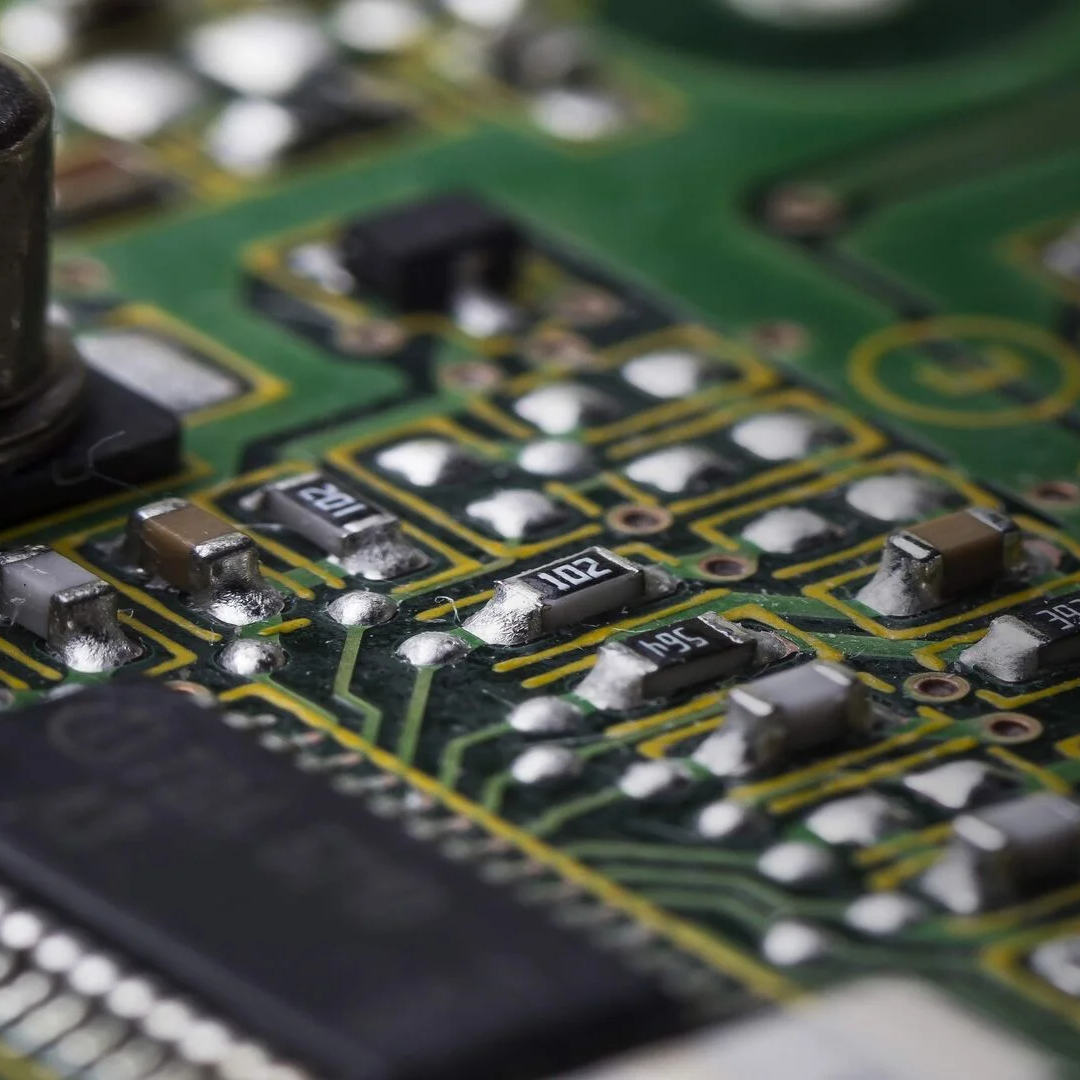

Re Lokela ho Nahana'ng ha re Khetha Solder, PCB le Packaging Materials?

Kopanong ea PCBA, khetho ea thepa e bohlokoa ho ts'ebetso ea boto le ho ts'epahala.Mona ke lintlha tse ling bakeng sa khetho ea solder, PCB le ho paka thepa: Mehaho ea khetho ea solder 1. Lead Free Solder vs Leaded Solder Lead-free solder e nkoa e le ea bohlokoa ka lebaka la botsoalle ba eona ba tikoloho,...Bala haholoanyane -

Lintlha tsa Seboka sa Medical PCBA Chip Processing Assembly ke life?

Tšebeliso ea liboto tsa potoloho e hatisitsoeng e fumaneha hohle liindastering tse sa tšoaneng.Kajeno re bua haholo ka litaba tse amanang le bongaka.Ha batho ba ntse ba sebelisa theknoloji e phahameng le e ncha ho tebisa butle-butle boithuto ba mahlale a bophelo.Mafu a ntseng a eketseha a lipatlisiso tsa bongaka le mekhoa ea kalafo ho ntlafatsa ...Bala haholoanyane -

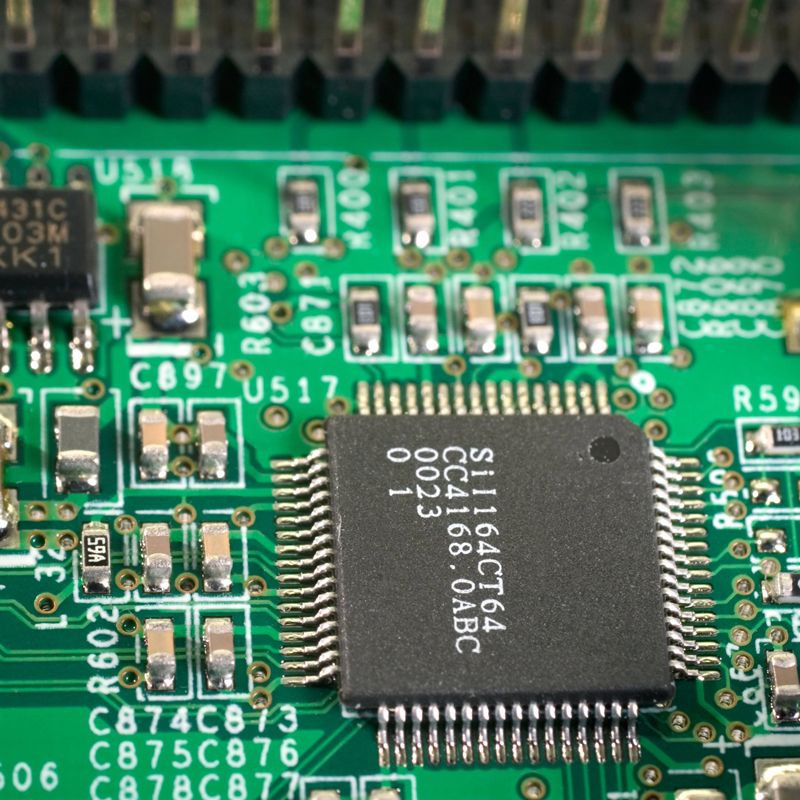

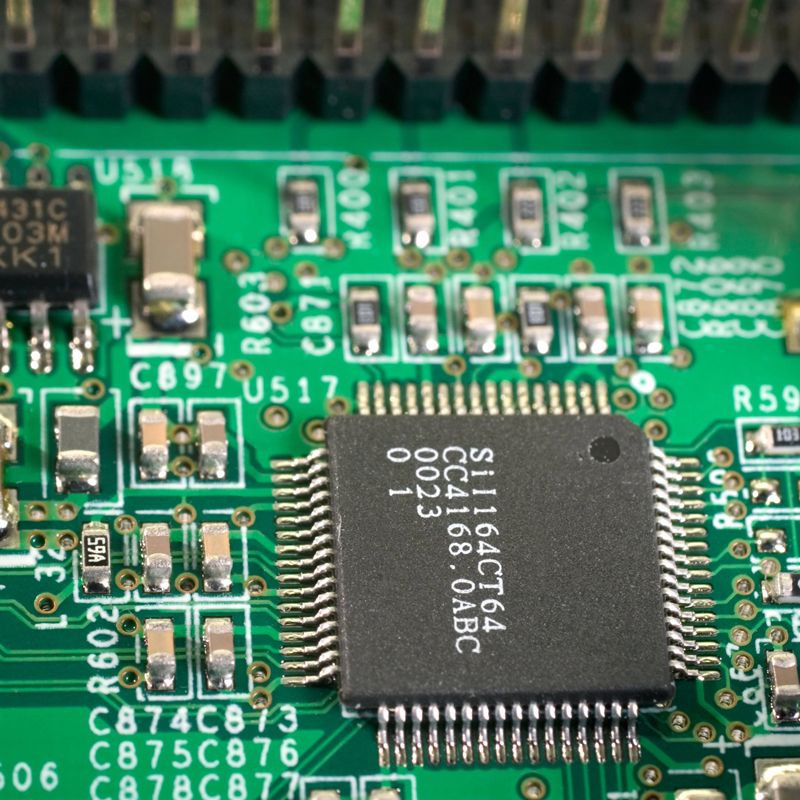

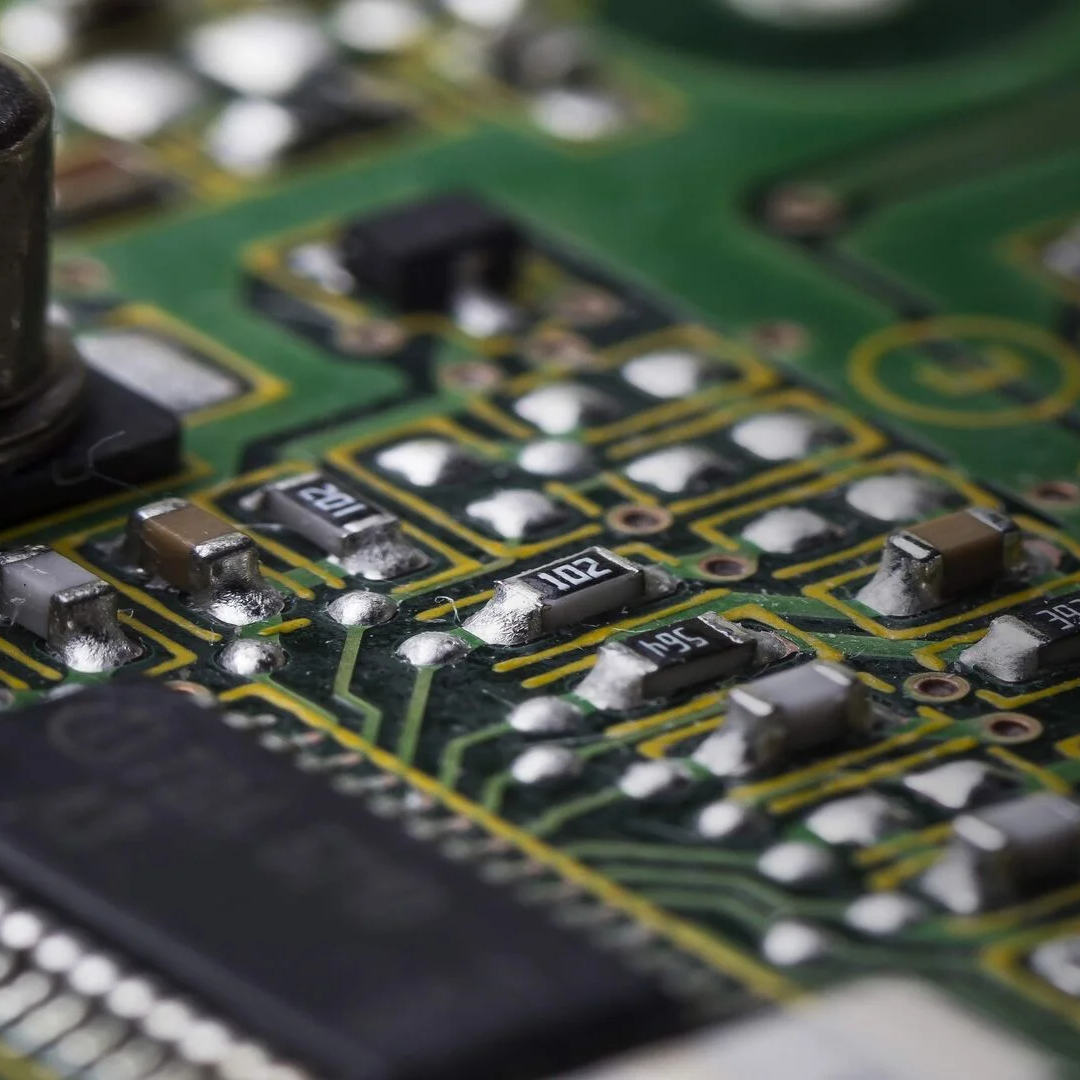

Litsela tsa ho lemoha Resistors le Capacitors ke life?

Ho tloha ka 2014, lisebelisoa tsa elektroniki tsa bareki, lihlahisoa tse nyane tse thehiloeng ho lisebelisoa, lihlahisoa tsa elektroniki tsa likoloi bakeng sa li-resistors tse kholo tsa chip li hlahisitse tlhoko e ntseng e eketseha.Haholo-holo, tlhoko ea elektroniki ea indasteri ea likoloi, ts'ebetso ea smt ea lihlahisoa e eketsehile haholo, empa data ea koloi ...Bala haholoanyane -

Sebopeho sa Mekhoa e Molemo ka ho Fetisisa: Botšepehi ba Letšoao le Tsamaiso ea Thermal

Layout ke e 'ngoe ea lintlha tse ka sehloohong tsa moralo oa PCBA ho netefatsa botšepehi ba matšoao le tsamaiso ea mocheso ea boto.Mona ke tse ling tsa mekhoa e metle ka ho fetisisa ea moralo oa PCBA ho netefatsa botšepehi ba matšoao le tsamaiso ea mocheso: Matšoao a Botšepehi Mekhoa e Molemo ka ho Fetisisa 1. Moralo o Rala: Sebelisa li-PCB tse ngata ho arola ...Bala haholoanyane -

Mokhoa oa ho khetha Semiconductor Package?

Ho fihlela litlhoko tsa mocheso oa kopo, baqapi ba hloka ho bapisa litšobotsi tsa mocheso tsa mefuta e fapaneng ea liphutheloana tsa semiconductor.Sengoliloeng sena, Nexperia e bua ka litsela tse futhumatsang tsa liphutheloana tsa eona tsa terata le liphutheloana tsa chip bond e le hore baqapi ba ka khetha e loketseng haholoanyane ...Bala haholoanyane -

Hobaneng ha Liboto tsa PCB li Impedance?

Hobaneng ha mapolanka a PCB a etsa impedance?Impedance - ha e le hantle, e bua ka ho hanyetsa le litekanyetso tsa para ea ho itšoara, hobane mohala oa PCB ho nahana ka ho kenngoa ha plug-in ea likarolo tsa elektronike, plug-in ka mor'a ho nahana ka conductivity le ts'ebetso ea phetisetso ea pontšo ...Bala haholoanyane -

VGA OUT PCB Design Menahano

VGA (Video Graphics Array) ke hore, video graphics array, e nang le qeto e phahameng, lebelo la ho bonts'a kapele, mebala e metle, joalo-joalo. VGA ha se feela sebopeho se tloaelehileng sa lisebelisoa tsa ponts'o tsa CRT, empa hape ke sebopeho se tloaelehileng sa lisebelisoa tsa LcD liquid crystal display. , e nang le mefuta e mengata ea lisebelisoa ...Bala haholoanyane -

Litekanyetso tsa tlhahlobo ea boto ea PCBA le mehato ea ho itšireletsa

PCBA boto PCBA boto tlhahlobo litekanyetso tsa?Litekanyetso tsa tlhahlobo ea boto ea I. PCB 1. Litšitiso tse tebileng (tse hlalosoang e le CR): liphoso leha e le life tse lekaneng ho baka kotsi ho 'mele oa motho kapa mochine kapa ho beha polokeho ea bophelo kotsing, joalo ka: ho se lumellane le melao ea tšireletso / ho chesa / motlakase. tshoso....Bala haholoanyane -

Ke Lintlha life tseo re Lokelang ho li Nahana ha re Khetha Mofani oa Boto ea Potoloho?

Ha u khetha mofani oa boto ea potoloho, ke habohlokoa ho nahana ka lintlha tse 'maloa ho netefatsa hore u fumana sehlahisoa sa boleng bo botle ka ho fetisisa ka theko e lekaneng.Mona ke tse ling tsa lintlha tseo u lokelang ho li hopola: Maemo a Boleng Boleng ke e 'ngoe ea lintlha tsa bohlokoa tse lokelang ho nahanoa ka ...Bala haholoanyane