PCB SMT Reflow Oven

PCB SMT Reflow Oven

Tlhaloso

| Lebitso la sehlahisoa | PCB SMT Reflow Oven |

| Mohlala | NeoDen IN12C |

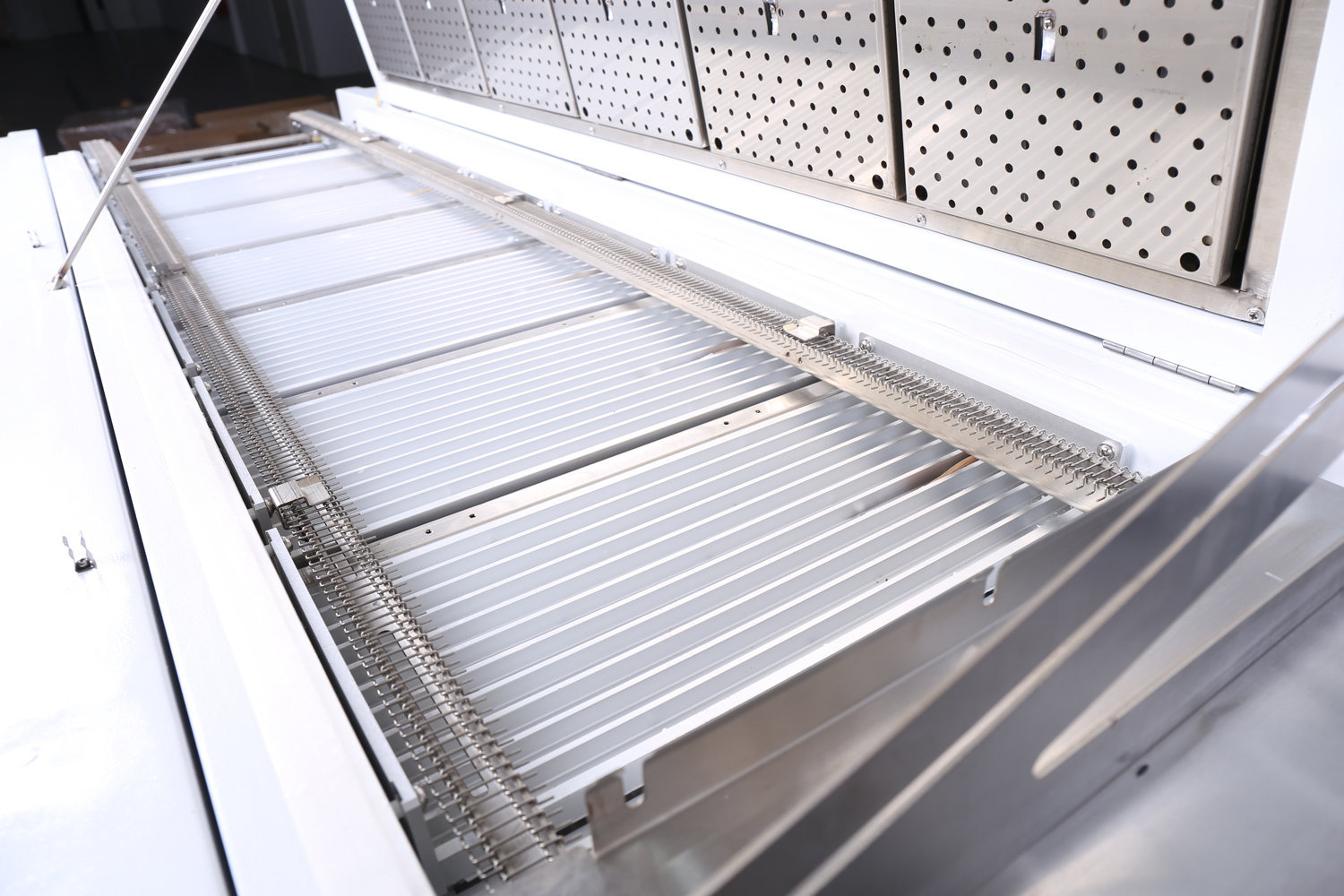

| Heating Zone Bongata | Holimo6 / Tlase6 |

| Fan e phodileng | Holimo4 |

| Lebelo la Conveyor | 50~600 limilimithara/mots |

| Mocheso Range | Mocheso oa kamore ke 300 ℃ |

| Ho Nepaha ha Mocheso | 1℃ |

| Phapang ea Mocheso oa PCB | ±2℃ |

| Bophahamo bo phahameng ba solder (mm) | 35mm (e kenyelletsa botenya ba PCB) |

| Max Soldering Width (PCB Width) | 350 limilimithara |

| Length Process Chamber | 1354 limilimithara |

| Phepelo ea Motlakase | AC 220v / mohato o le mong |

| Boholo ba Mochini | L2305mm×W612mm×H1230mm |

| Nako ea ho futhumatsa | 30 mets |

| Boima bo kahare | 300Kgs |

Lintlha

Libaka tse 12 tsa ho futhumatsa

Mocheso o tšoanang

Ho nepahala ho laola mocheso o phahameng

Sebaka sa ho pholisa

Moqapi oa moea o potolohang o ikemetseng

E arola tšusumetso ea tikoloho ea kantle

Ho boloka matla le Eco-friendly

Sistimi ea ho sefa mosi oa welding

matla a tlase le litlhoko tsa phepelo

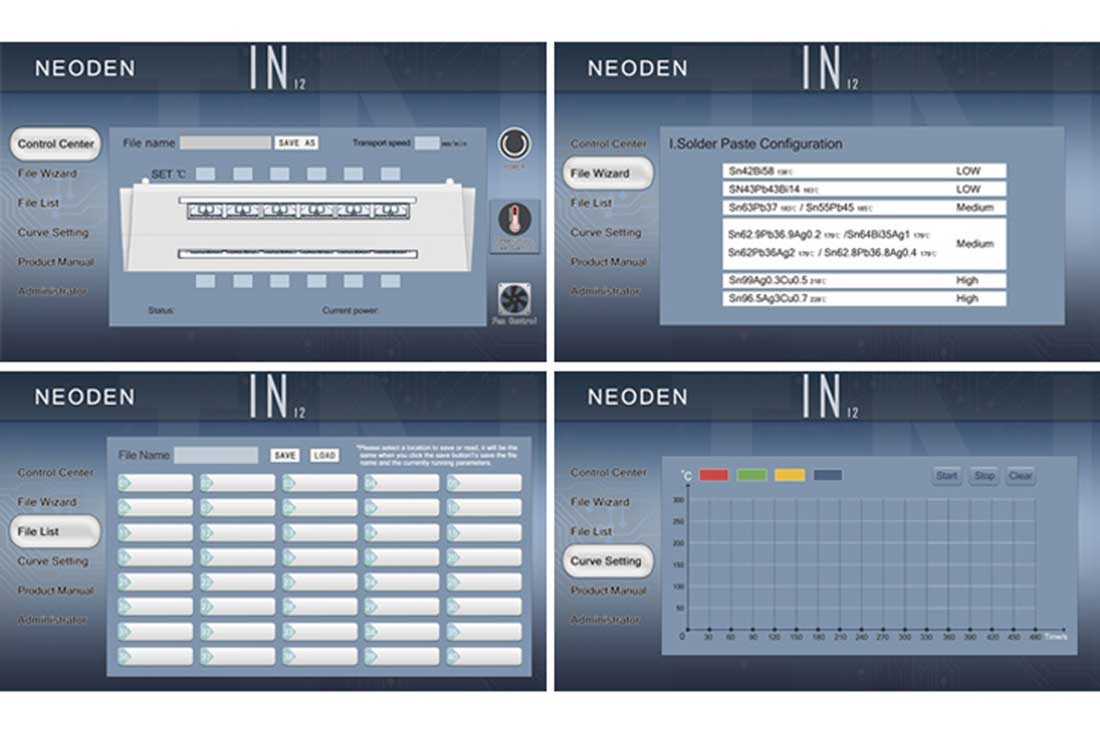

Phanele ea ts'ebetso

Moralo oa skrine o patiloeng

E loketse lipalangoang

Tsamaiso e bohlale ea taolo

Sistimi e tsoetseng pele e bohlale ea taolo

Thempereichara curve e ka bontšoa

Ponahalo e ntle

Tumellanong le tikoloho ea tšebeliso ea maemo a holimo

E bobebe, miniaturization, setsebi

Kenyelletso e Khutšoanyane

Sistimi ea taolo e na le litšobotsi tsa kopanyo e phahameng, karabelo e nakong, sekhahla se tlase sa ho hloleha, tlhokomelo e bonolo, joalo-joalo.

Moqapi o ikhethang oa mochini oa ho futhumatsa, o nang le taolo e phahameng ea mocheso o nepahetseng, kabo ea mocheso o ts'oanang sebakeng sa matšeliso a mocheso, ts'ebetso e phahameng ea matšeliso a mocheso, tšebeliso e tlaase ea matla le litšobotsi tse ling.

E bohlale, e kopantsoe le algorithm ea taolo ea PID ea sistimi e bohlale e ntlafalitsoeng, e bonolo ho e sebelisa, e matla.

Moqapi o ikhethang oa poleiti ea ho futhumatsa ka katleho e tiisa hore ho pholile ha mokhoa o ts'oanang ka mor'a hore lisebelisoa li khaotse ho futhumatsa, ho thibela ka katleho likarolo hore li senyehe ke ho fokotseha ka potlako ha mocheso le ho senyeha ho bakoang.

Lebokose la mocheso le ka hare le entsoe ka tšepe e sa hloekang, e nang le botsoalle ba tikoloho le e sa nkhang hamonate, 'me lehlakore le ka hare le na le k'hothone ea mocheso oa mocheso ho thibela ka katleho tahlehelo ea mocheso.

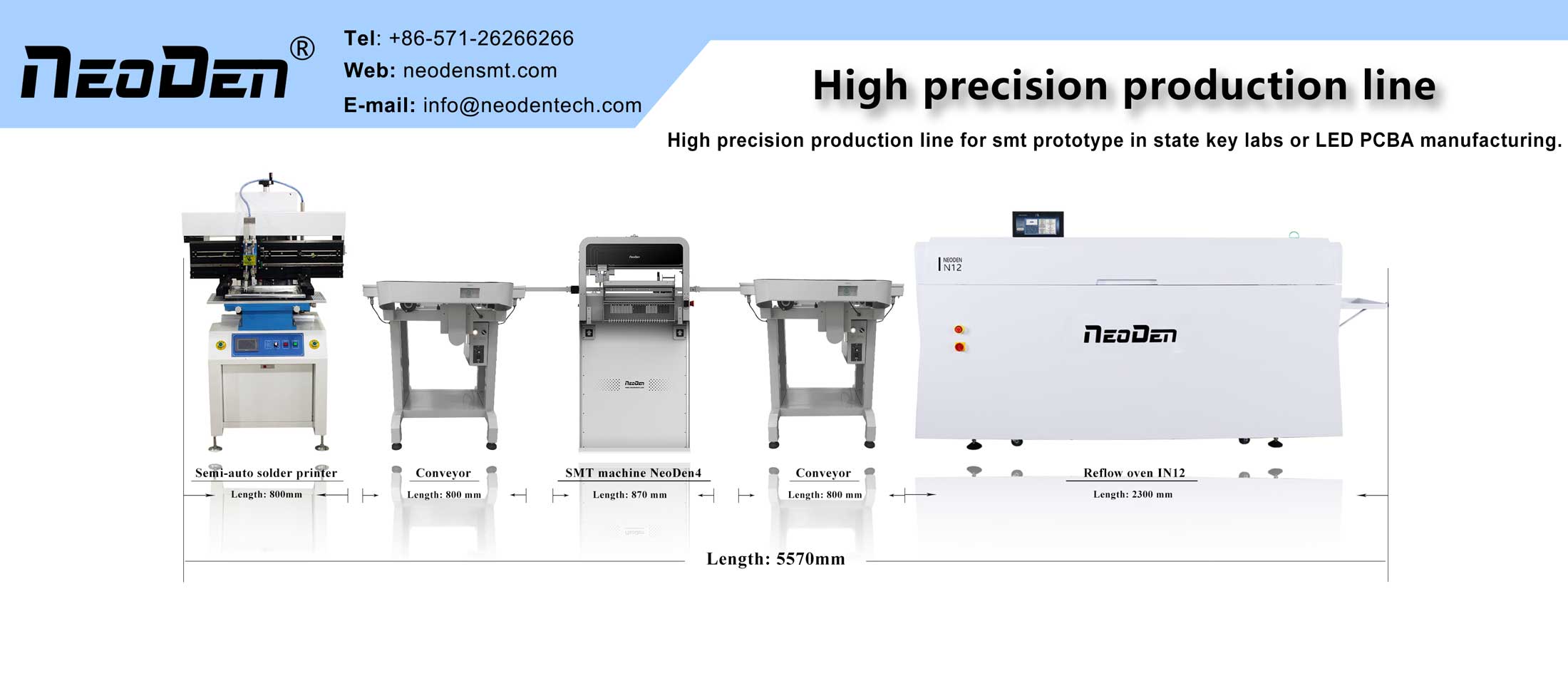

Fana ka mohala o le mong oa tlhahiso ea kopano ea SMT

Lihlahisoa tse amanang

LBH

Q1.Ts'ebeletso ea hau ea thomello ke efe?

A: Re ka fana ka litšebeletso bakeng sa ho tsamaisa likepe, ho kopanya thepa, phatlalatso ea meetlo, ho lokisetsa litokomane tsa ho romela le ho fana ka bongata boema-kepeng ba likepe.

Q2. Nako ea hau ea delibari ke efe?

A: Nako ea rona e tloaelehileng ea ho tsamaisa ke FOB Shanghai.

Re boetse re amohela EXW, CFR, CIF, DDP, DDU joalo-joalo.

Re tla u fa litefiso tsa thomello, 'me u ka khetha e loketseng le e sebetsang hantle bakeng sa hau.

Q3.Lihlahisoa tsa hau ke life?

Mochini oa A. SMT, AOI, onto ea ho phalla hape, mochini o kenyang PCB, printa ea stensele.

Q4. Ho thoe'ng ka nako ea pele ea tlhahiso ea bongata?

A: Matsatsi a ho sebetsa a 15-30 bakeng sa tlhahiso ea bongata.

E itšetlehile ka bongata ba hau, 'me re tla leka ka hohle ho finyella litlhoko tsa hau.

Q5. Lipehelo tsa hau tsa ho fana ke life?

A: EXW, FOB, CIF, joalo-joalo.

Mabapi le rona

Feme

Boemo ba Khoebo

E thehiloe ka 2010 ka basebetsi ba 100+ & 8000+ Sq.m.fektheri ea litokelo tsa thepa e ikemetseng, ho netefatsa tsamaiso e tloaelehileng le ho finyella liphello tse ngata tsa moruo hammoho le ho boloka litšenyehelo.

E na le setsi sa hau sa mochini, se kopanyang litsebo, tester le baenjiniere ba QC, ho netefatsa bokhoni bo matla ba ho etsa mechini ea NeoDen, boleng le phano.

Lihlopheng tse 3 tse fapaneng tsa R&D tse nang le kakaretso ea lienjineri tse 25+ tsa litsebi tsa R&D, ho netefatsa tsoelopele e betere le e tsoetseng pele le boqapi bo bocha.

Ba nang le boiphihlelo le ba hloahloa ba tšehetso ea Senyesemane le lienjiniere tsa litšebeletso, ho netefatsa karabelo e potlakileng nakong ea lihora tse 8, tharollo e fana ka nako ea lihora tse 24.

E ikhethang har'a bahlahisi bohle ba Machaena ba ngolisitseng le ho amohela CE ke TUV NORD.

Pontšo

Setifikeiti

Haeba o hloka, ka kopo ikutloe u lokolohile ho ikopanya le rona bakeng sa tlhaiso-leseling e batsi.

Q1:U rekisa lihlahisoa life?

A: Khamphani ea rona e sebetsana le lihlahisoa tse latelang:

Lisebelisoa tsa SMT

Lisebelisoa tsa SMT: Liphepelo, likarolo tsa Feeder

Li-nozzle tsa SMT, mochini o hloekisang li-nozzle, filthara ea nozzle

Q2:Nka fumana khotheishene neng?

A: Re atisa ho qotsa pele ho lihora tse 8 ka mor'a hore re fumane potso ea hau.Haeba u potlakile haholo ho fumana theko, ka kopo re bolelle e le hore re tla nka potso ea hau pele.

Q3:A na nka etela feme ea hau?

A: Ka mokhoa oohle, re amohela ka mofuthu ho fihla ha hao, Pele u tloha naheng ea heno, ka kōpo re tsebise.Re tla u bontša tsela le ho hlophisa nako ea ho u lata haeba ho khonahala.