1) Stencil ea electroforming

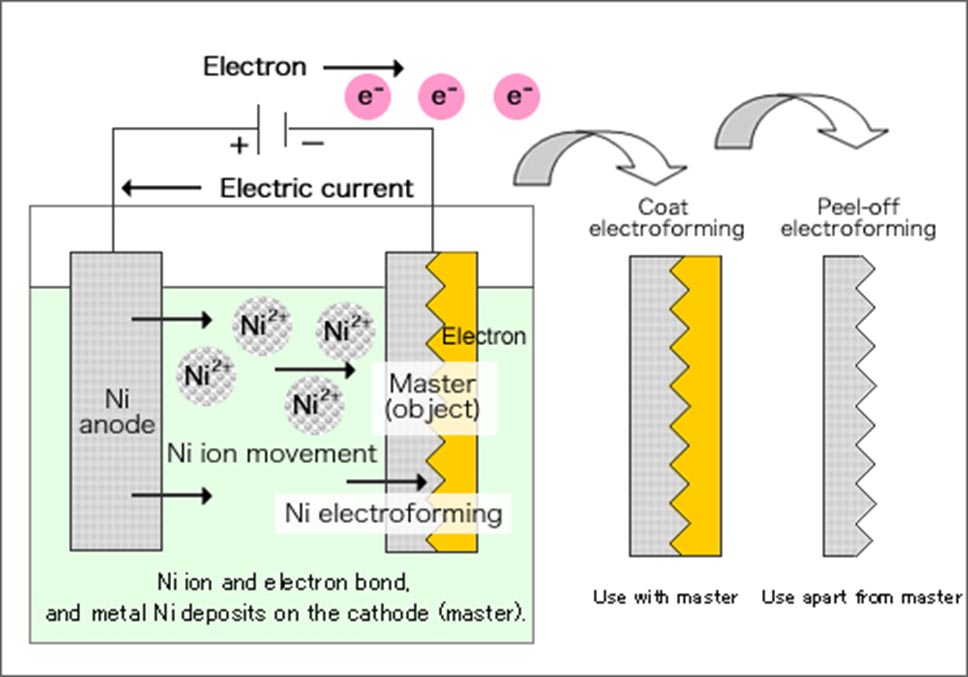

Molao-motheo oa tlhahiso ea stencil electroformed: thempleite electroformed e entsoe ka ho hatisa lintho tse bonahalang photoresist ka tšepe conductive tšepe botlaaseng poleiti, 'me joale ka masking hlobo le ultraviolet pepesa,' me joale thempleite tšesaane e electroformed ka mokelikeli electroforming.Ha e le hantle, electroforming e tšoana le electroplating, ntle le hore letlapa la nickel ka mor'a electroforming le ka tlosoa ho tloha poleiti e ka tlase ho etsa stencil.

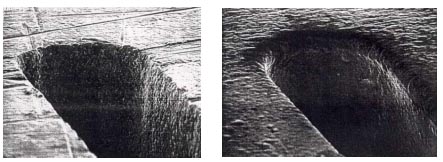

Stencil ea electroforming e na le litšobotsi tse latelang: ha ho na khatello ea kelello ka har'a letlapa la tšepe, lerako la sekoti le boreleli haholo, stencil e ka ba botenya leha e le bofe (ka har'a 0.2mm, e laoloang ke nako ea electroforming), bothata ke hore litšenyehelo li phahame.Setšoantšo se latelang ke papiso ea lerako la tšepe la laser le lebota la tšepe le entsoeng ka electroformed.Lerako le boreleli la lesoba la tšepe ea electroformed le na le phello e ntle ea ho senya ka mor'a ho hatisa, e le hore karolelano ea ho bula e ka ba tlase ho 0,5.

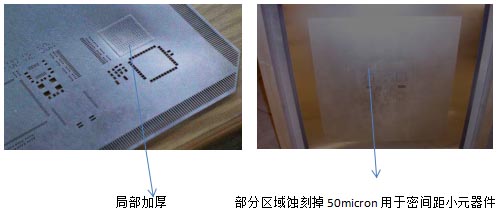

2) Stencil ea lere

Letlooa la tšepe le hatang le ka tšeloa sebakeng sa heno kapa la tšesaane.Karolo e teteaneng e sa fellang e sebelisetsoa ho hatisa liphahlo tsa solder tse hlokang palo e kholo ea peista ea solder, 'me karolo e teteaneng e lemohuoa ka electroforming,' me litšenyehelo li phahame.Ho fokotseha ho finyelloa ka ho chesoa ka lik'hemik'hale.Karolo e tšesaane e sebelisetsoa ho hatisa liphahlo tsa likaroloana tse nyenyane, tse etsang hore phello ea ho senya e be betere.Basebelisi ba sa tsotelleng litšenyehelo ba khothaletsoa ho sebelisa etching ea lik'hemik'hale, e theko e tlase.

3) Nano Ultra Coating

Ho roala kapa ho roala lera la nano-coating holim'a letlooeng la tšepe, nano-coating e etsa hore lebota la lesoba le lelekise peista ea solder, kahoo phello ea ho senya e molemo, le botsitso ba molumo oa khatiso ea solder peista e tsitsitse haholoanyane.Ka tsela ena, boleng ba khatiso bo tiisitsoe haholoanyane, 'me palo ea ho hloekisa le ho hlakola mesh ea tšepe le eona e ka fokotseha.Hona joale, mekhoa e mengata ea malapeng e sebetsa feela ka lera la nano-coating, 'me phello e fokotsehile ka mor'a palo e itseng ea khatiso.Ho na le li-nano-coatings tse koahetsoeng ka ho toba holim'a letlooeng la tšepe, tse nang le phello e ntle le e tšoarellang, 'me ha e le hantle litšenyehelo li phahame.

3. Double solder peista ho bōpa tshebetso.

1) Ho hatisa/Ho hatisa

Mechini e 'meli ea khatiso e sebelisoa ho hatisa le ho theha solder paste.Ea pele e sebelisa stencil e tloaelehileng ho hatisa liphahlo tsa likaroloana tse nyenyane tse nang le molumo o motle, 'me ea bobeli e sebelisa stencil ea 3D kapa stencil ea mohato ho hatisa liphahlo tsa likarolo tse kholo.

Mokhoa ona o hloka mechine e 'meli ea khatiso, 'me theko ea stencil le eona e holimo.Haeba stencil ea 3D e sebelisoa, ho hlokahala sekoti sa comb, se eketsang litšenyehelo le katleho ea tlhahiso le eona e tlaase.

2) Ho hatisa / ho fafatsa thini

Mochine oa pele oa khatiso oa "solder paste" o hatisa lipampitšana tsa likaroloana tse nyane, 'me khatiso ea bobeli ea inkjet e hatisa likaroloana tse kholo.Ka tsela ena, phello ea solder paste molding e ntle, empa litšenyehelo li phahame 'me katleho e tlaase (ho itšetlehile ka palo ea likarolo tse kholo tsa likarolo).

Basebelisi ba ka khetha ho sebelisa litharollo tse 'maloa tse kaholimo ho latela maemo a bona.Mabapi le litšenyehelo le katleho ea tlhahiso, ho fokotsa botenya ba stencil, ho sebelisa li-stencil tsa karo-karolelano ea sebaka se tlaase se hlokahalang, le li-stencil tsa mehato ke khetho e nepahetseng haholoanyane;basebelisi ba nang le tlhahiso e tlase, litlhoko tsa boleng bo holimo, le basebelisi ba sa tsotelleng litšenyehelo ba ka khetha Lenaneo la khatiso / jet printing.

Nako ea poso: Aug-07-2020