Mochini oa onto oa ho roala oa LED Reflow Soldering

Mochini oa onto oa ho roala oa LED Reflow Soldering

Tlhaloso

| Lebitso la sehlahisoa | Mochini oa onto oa ho roala oa LED Reflow Soldering |

| Mohlala | NeoDen IN12C |

| Heating Zone Bongata | Holimo6 / Tlase6 |

| Fan e phodileng | Holimo4 |

| Lebelo la Conveyor | 50~600 limilimithara/mots |

| Mocheso Range | Mocheso oa kamore ke 300 ℃ |

| Ho Nepaha ha Mocheso | 1℃ |

| Phapang ea Mocheso oa PCB | ±2℃ |

| Bophahamo bo phahameng ba solder (mm) | 35mm (e kenyelletsa botenya ba PCB) |

| Max Soldering Width (PCB Width) | 350 limilimithara |

| Length Process Chamber | 1354 limilimithara |

| Phepelo ea Motlakase | AC 220v / mohato o le mong |

| Boholo ba Mochini | L2305mm×W612mm×H1230mm |

| Nako ea ho futhumatsa | 30 mets |

| Boima bo kahare | 300Kgs |

Lintlha

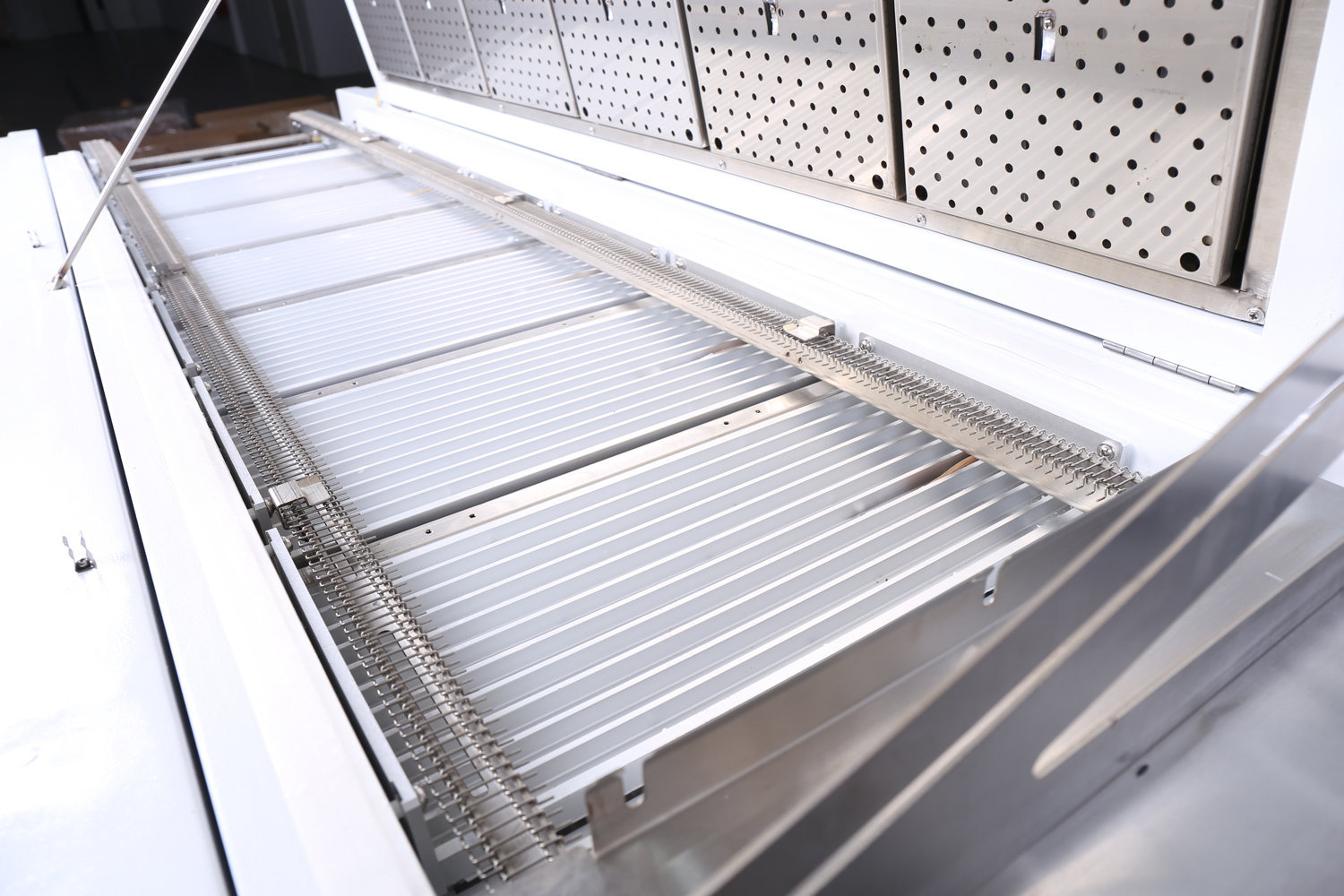

Libaka tse 12 tsa ho futhumatsa

Mocheso o tšoanang

Ho nepahala ho laola mocheso o phahameng

Sebaka sa ho pholisa

Moqapi oa moea o potolohang o ikemetseng

E arola tšusumetso ea tikoloho ea kantle

Ho boloka matla le Eco-friendly

Sistimi ea ho sefa mosi oa welding

matla a tlase le litlhoko tsa phepelo

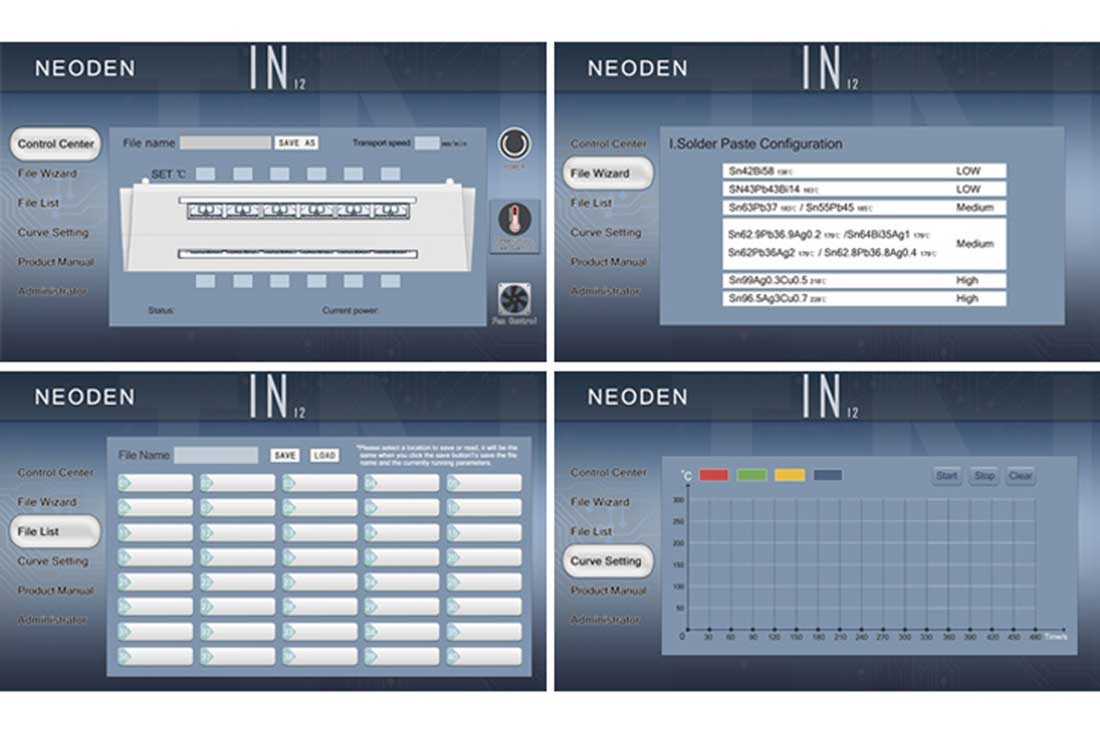

Phanele ea ts'ebetso

Moralo oa skrine o patiloeng

E loketse lipalangoang

Tsamaiso e bohlale ea taolo

Sistimi e tsoetseng pele e bohlale ea taolo

Thempereichara curve e ka bontšoa

Ponahalo e ntle

Tumellanong le tikoloho ea tšebeliso ea maemo a holimo

E bobebe, miniaturization, setsebi

Likaroloana

1. Tsamaiso ea tsamaiso e na le litšoaneleho tsa ho kopanya ho phahameng, karabelo e nakong, tekanyo e tlaase ea ho hlōleha, tlhokomelo e bonolo, joalo-joalo.

2. Moea o chesang convection, ts'ebetso e babatsehang ea ho tjheseletsa.

3. Taolo e bohlale, sensor ea mocheso e phahameng-sensitivity, botsitso bo sebetsang ba mocheso.

4. setsebi, se ikhethang sa 4-way board holim'a mocheso oa mocheso oa tsamaiso ea ho hlahloba mocheso, e le hore ts'ebetso ea sebele ka nako e nepahetseng le e pharaletseng ea lintlha tsa maikutlo, esita le bakeng sa lihlahisoa tse rarahaneng tsa elektronike li ka atleha.

5. E ka boloka lifaele tse 40 tse sebetsang.

6. Moqapi oa moea o potolohang o ikemetseng oa sebaka se pholileng, se arohaneng ka ho feletseng le tikoloho e ka ntle ho mocheso oa mocheso o ka hare.

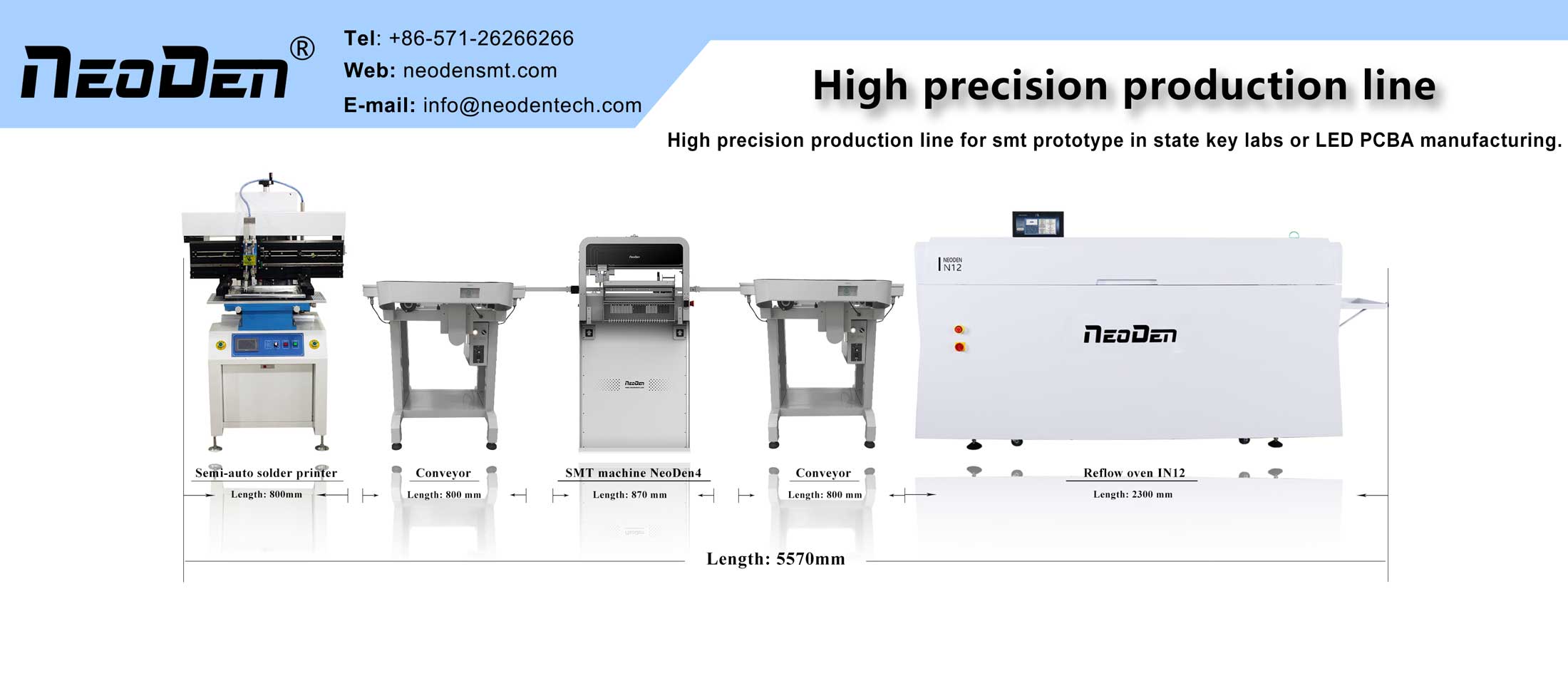

Fana ka mohala o le mong oa tlhahiso ea kopano ea SMT

Lihlahisoa tse amanang

LBH

Q1:Nka reka mochini ho uena joang?

A: (1) Ikopanye le rona ka mohala kapa ka e-mail.

(2) Buisana le ho netefatsa theko ea ho qetela, ho romella, mokhoa oa ho lefa le lipehelo tse ling.

(3) U romelle invoice ea perfroma 'me u netefatse taelo ea hau.

(4) Etsa tefo ho latela mokhoa o behiloeng ho proforma novoice.

(5) Re lokisa odara ea hau ho latela invoice ea proforma kamora ho netefatsa tefo ea hau e felletseng.Le ho hlahloba boleng ba 100% pele ho romelloa.

(6) Romella odara ea hau ka tsela ea Express kapa ka moea kapa ka leoatle.

Q2:Na u khamphani ea khoebo kapa moetsi?

A: Re baetsi ba litsebi ba khethehileng ho SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line le lihlahisoa tse ling tsa SMT.

Q3:Na ho thata ho sebelisa mechine ee?

A: Che, ha ho thata ho hang.

Bakeng sa bareki ba rona ba pele, bonyane matsatsi a 2 a lekane ho ithuta ho sebelisa mechini.

Mabapi le rona

Feme

Pontšo

Setifikeiti

Haeba o hloka, ka kopo ikutloe u lokolohile ho ikopanya le rona bakeng sa tlhaiso-leseling e batsi.

Q1:U rekisa lihlahisoa life?

A: Khamphani ea rona e sebetsana le lihlahisoa tse latelang:

Lisebelisoa tsa SMT

Lisebelisoa tsa SMT: Liphepelo, likarolo tsa Feeder

Li-nozzle tsa SMT, mochini o hloekisang li-nozzle, filthara ea nozzle

Q2:Nka fumana khotheishene neng?

A: Re atisa ho qotsa pele ho lihora tse 8 ka mor'a hore re fumane potso ea hau.Haeba u potlakile haholo ho fumana theko, ka kopo re bolelle e le hore re tla nka potso ea hau pele.

Q3:A na nka etela feme ea hau?

A: Ka mokhoa oohle, re amohela ka mofuthu ho fihla ha hao, Pele u tloha naheng ea heno, ka kōpo re tsebise.Re tla u bontša tsela le ho hlophisa nako ea ho u lata haeba ho khonahala.